Colbert Infrared Services Inc.

For more than 42 years we have gone to sea serving military and civilian maritime all over the world. We got our start onboard U.S. Navy Aircraft Carriers, Military Sealift Command, and U.S. Coast Guard ships back in the 1970s and we are still the company of choice when it comes to unmatched quality and professional integrity. Colbert Infrared has always had your back!

The Challenges – “How do you eat an Elephant?”

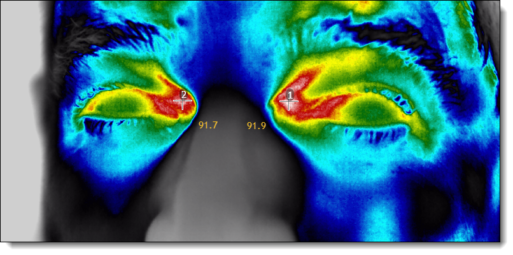

You can not leave anything to chance when it comes to the safety and reliability of electrical equipment when you are in heavy seas in the middle of the ocean. The conditions for conducting an infrared electrical inspection on a ship are some of the most challenging environments on earth, or in this case at sea. If you are not on top of your game then you do not have any business being out there. There are lives on the line if you don’t know what you are doing.

It is for this reason that we have always lead the way when it comes to our testing procedures, professional accountability, data analysis, and reporting.

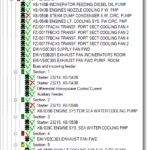

You must have 100% accountability

- What is to be tested,

- What has been tested?

- What can not be tested?

Equipment needs to be categorized by its cruciality to operations and the consequence of failure:

- Critical

- Essential

- Non-essential

The importance of having a proven data accountability solution in the field.

There are 1,000’s of pieces of equipment to be tested that are spread over 100’s of locations on a ship. You need to know what is running and where it is, no stone can be left unturned, there is too much at risk!

When the Chief Engineer asks you:

- What have you tested?

- What still needs to be tested?

- How many of the past problems have been fixed, or are they getting worse? And by how much?

- What new problems have you found? And how bad are they?

- What equipment were you not able to test, and were there any past problems on them?

If you can not answer these questions immediately, then he will let you know that “you have absolutely no business being on his ship and wasting his time!”

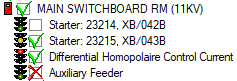

The Solution – How Colbert Infrared handles Elephants: Thermal Trend – Lean

Colbert Infrared has been the leader in developing the testing procedures and methods for 100% professional accountability in the Maritime industry by building on our experience of over 42 years. These inspection methods have become the backbone of how infrared electrical/mechanical inspection programs are built. Utilizing a SQL: RDMS (SQL: Relational Database Management System) in the field called Thermal Trend we are able to provide our technical staff critical information in the correct order and format for them to be able to make real-time critical evaluations as to equipment status.

Without using Thermal Trend – Lean, you would be like a blind man in a minefield not knowing where you are going, and where not to step! Thermal Trend – Lean provides us with an unmatched 100% professional accountability solution for data collection and reconciliation in the field, where and when you need it the most.

- Our technical staff has the complete aggregate of every inspection that has ever been done, on every piece of equipment while they are doing the inspection.

- All equipment is inventoried and barcode labeled for correct identification and quick searching in Thermal Trend – Lean.

- Managing all of what is to be tested vs. what is tested and what has been tested provides engineering with a complete perspective on inspection activities.

- Easily prioritizing what is to be tested while it is running.

- Daily Reporting of Inspection status, and all problems conditions.

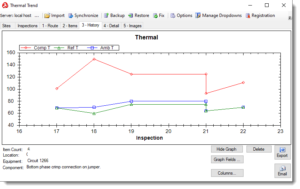

Advanced Reporting provides you with an unmatched perspective as to problem conditions.

Since Thermal Trend – Lean is built on SQL: RDMS platform, reporting is fast and complete containing:

- Executive Summary

- Prioritized List of Open Problems

- Detailed Open Problems that were found with trending of readings over time.

- Closed Problems

- The complete inventory of test statues of all equipment and locations

Thermal Trend – Insight BI

A web-based interactive perspective utilizing an interactive graphical user interface allows for drilling down into inspection data to get the most advanced web-based reporting perspective possible. you can get that 30,000 ft. perspective of the entire status of the Fleet, or do a deep dive into a specific piece of equipment test history and trend problem conditions from cradle to grave.