NEWS

The Benefits of Integrating “Lean Thinking” Concepts

Lean Thinking is nothing new, nor many of its concepts, but the real value is in how these concepts are integrated into a total solution…

Read MoreView All News

Points to Consider When Choosing Inspection Company

Look for companies that are stable and have experience using infrared in a variety of applications…

Read MoreView All News

Infrared Electrical Inspections

What is the Required Frequency

There are many documents defining the specifications for reducing/eliminating electrical safety hazards and prevent equipment failures, while at the same time increasing a facility operating up-time…

Read MoreView All News

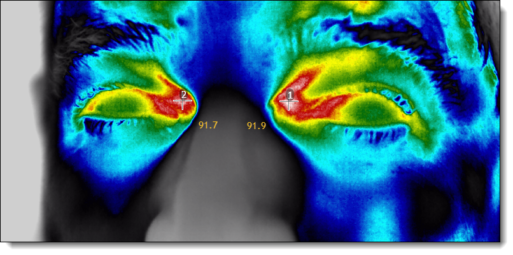

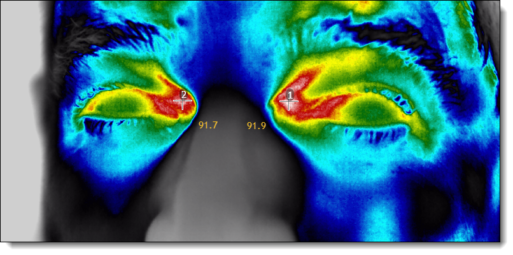

Infrared Imaging and Thermography - Facts vs. Fantasy: The Truth for COVID-19

The term Infrared or IR can conjure up a lot of crazy or “Terrifying” ideas as to what it is and how it is used.

Read MoreView All News

The Placement of Infrared Windows in High Voltage Switchgear

Today the utilization of using Infrared Windows / View Ports for the scanning of electrical connections in High Voltage Switch Gear is becoming very common for many reasons.

Read MoreView All News

The Importance of Data and Trends in Infrared Thermography

You must have the data, correct data, and then it’s what you do with the data that allows you to have an informed perspective of the ever-changing dynamic situations and be able to make the right decisions to make improvements.

Read MoreView all news

The Truth About Infrared Temperature Measurement For COVID-19 Scanning of Body Temperature

Infrared/thermal imaging cameras do not actually measure temperature — they measure the radiated energy of the surface area that they are viewing.

Read MoreView all News