Thermal Trend – Lean is how we manage your Predictive Maintenance Program!

Your facility’s, PdM/Condition Monitoring Program, Key assets can not be honestest managed any other way. This is how we Eat The Elephant and manage your data. It’s not the IR camera, that defines your program…“Your IR Program is defined by how your data is managed!”

Thermal Trend – Lean allows us to bring all of your critical information “Out” on the plant floor to make critical decisions, where and when its need.

Colbert Infrared all of the information needed to easily locate equipment that is to be inspected, review equipment’s past problem history, and quickly document any problem conditions that have been found. Eliminates data errors, redundant data entry and exponentially increases our “Thermographers Historical Knowledge” of your equipment while they are conducting your inspection.

Thermal Trend – Lean DB as compared to other data collection methods:

- No 3rd party hosting “In the Cloud” of your Data as in SAAS (Software As A Service) Where your critical data is vulnerable to being exposed across the internet.

“Designed by Thermographers, for Thermographers ” ©

At the core of Thermal Trend, Lean DB is a powerful Microsoft SQL relational database that manages all the data associated with your Infrared PdM program — from managing your inspection schedule to generating your reports.

The power of using Thermal Trend Lean DB in the field is that allows us build your database without any time lost in conducting your inspection. This saves time and offers the assurance that your equipment’s inventory and associated inspection records will be complete and accurate every time! We will be always working with the “complete aggregate of all of your past inspection data in the field” during your inspection. This is when and where it is need so that analyses problems problems will provide you with 100% professional accountability.

Please take a tour of Thermal Trend – Lean below by exploring the tab navigation of how we set up your sites, and manage your IR Programs!

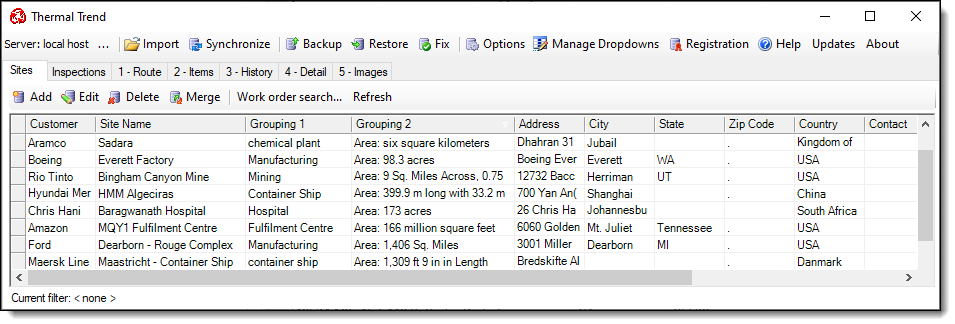

The "Sites" tab is our starting point of where we create the site for your account.

There are no limit's to the number of Sites that your Account can have. From a small facility to a global enterprise with thousands of buildings and millions of assets, we have the ability to easily handle any size customers needs. This provides you with a top down perspective of all of your sites/locations with the 30,000 foot perspective of what is happening at each of your facility's sites.

Important Note: Thermal Trend - Lean is a Enterprise level Fully Relational Database solution based on a secure, state of the art Microsoft SQL platform, which means that your critical infrastructure data is not "Up in the Cloud", or vulnerable to exploitation like "SAAS"i.e. (Software As A Service) products are.

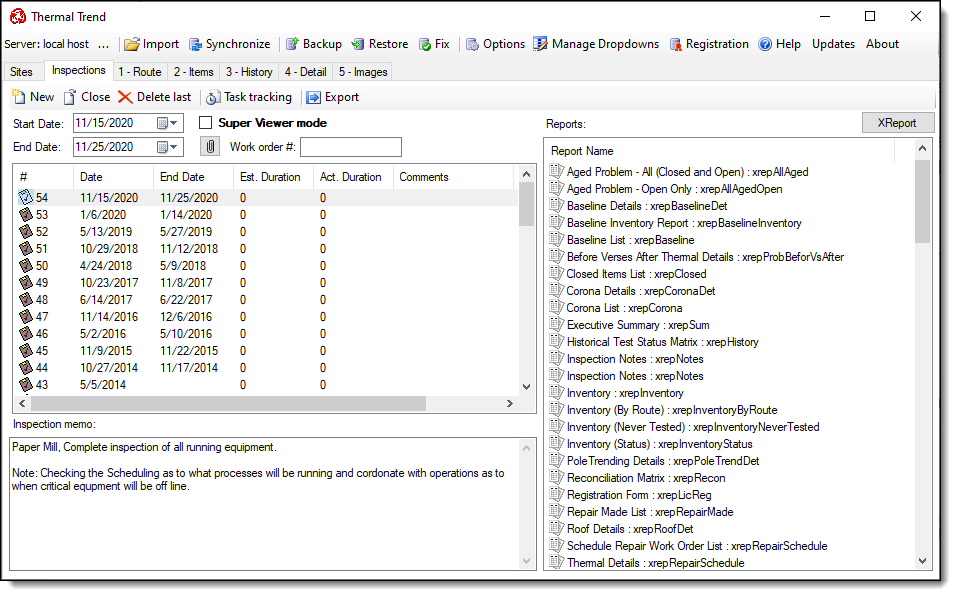

Next is the Inspection tab that will index all of the inspections that have ever been preformed at your facilities.

The Inspections Tab

From the Site Tab to the Inspections Tab, We index each site wide or specific inspection requirements that provide you with the complete aggregate of all of your past inspections at each of your at individual sites. We can easily run an unlimited verity of reports for your specific needs that are truly unmatched in the industry for Professional International Accountability.

It’s that simple.

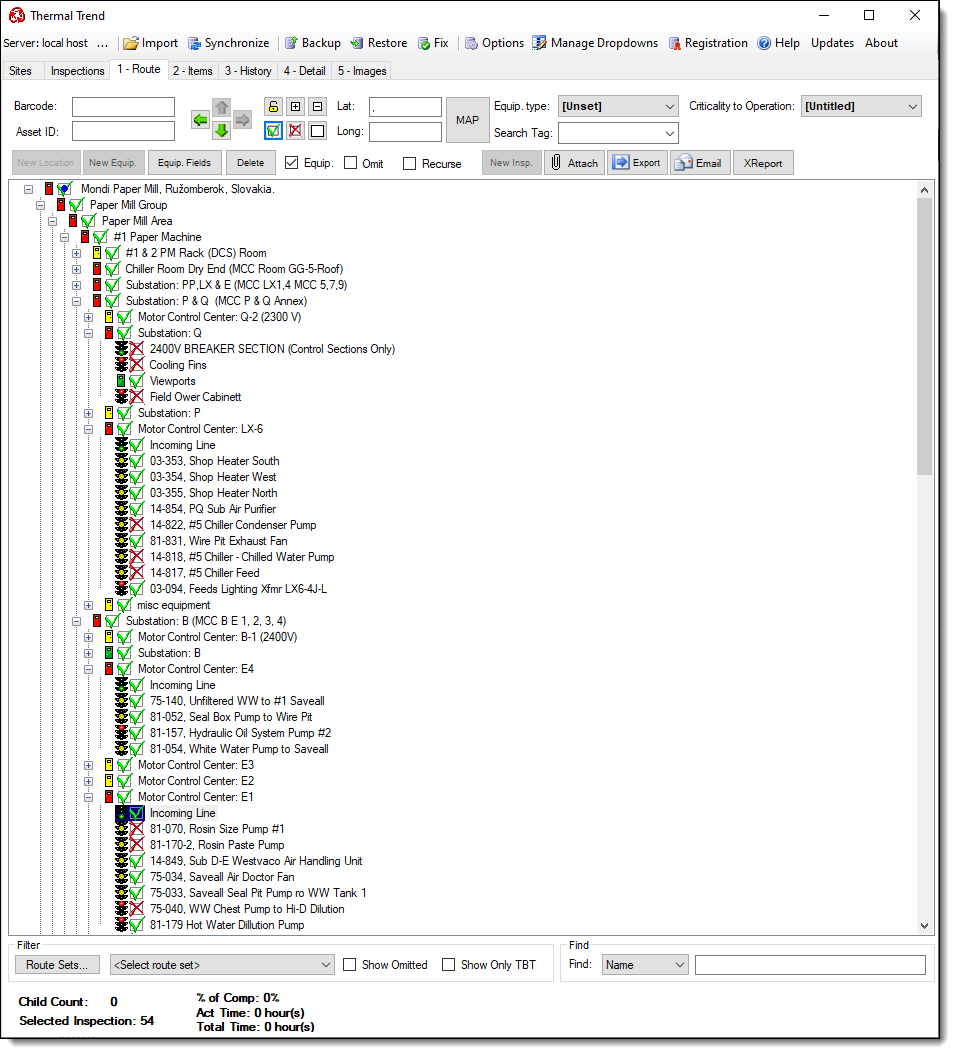

The 1 - Route tab is the foundation of your Thermal Trend - Lean database!

This is where we geographically list all of your equipment based on it's location within your facility. We will breakdown each location and sub locations and list all of your equipment that is to be tested.

Each piece of equipment will be labeled with a Barcode tag, RF-ID tag, GPS location depending on what is appropriate for that assert for fast, accurate and error proof identification of the equipment during the inspection.

Find your equipment quickly and easily

Easily navigate through your equipment inspection list by using a “hierarchal route view” of where your equipment is located.

You can organize your routes in any way you like, with the flexibility to work any way you choose.

The user interface is intuitive and powerful.

The standard explorer view lets you easily navigate through your facilities equipment.

Key information about location, equipment and problems remains on the screen in front of you.

• Add and or edit equipment (stop light icons) and locations (doors icons) to your inspection routes.

• Use barcodes, asset IDs, GPS or name to quickly search for a specific location or equipment in your route inventory.

• Check off what has been tested or not-tested.

Easily navigate through your equipment inspection list by using a “hierarchical route view” of where your equipment is located. You can organize your routes in any way you like, with the flexibility to work any way you choose. The user interface is intuitive and powerful.

The Route tab allows us to easily explorer and navigate through your facility's locations and equipment. Key information about problems what is to be tested, tested and not-tested status, as well as existing past/present problem status is presented in one simple simple visual experience that presents to us all of the critical information that we will need to drill down to to provide you with the most professional service possible.

- Locations (doors icons)

- Equipment (traffic light icons)

- Check boxes, (Green Check for tested, Red X for Not tested)

Note: Colored doors/locations, and equipment icons reflect the problem status. ®

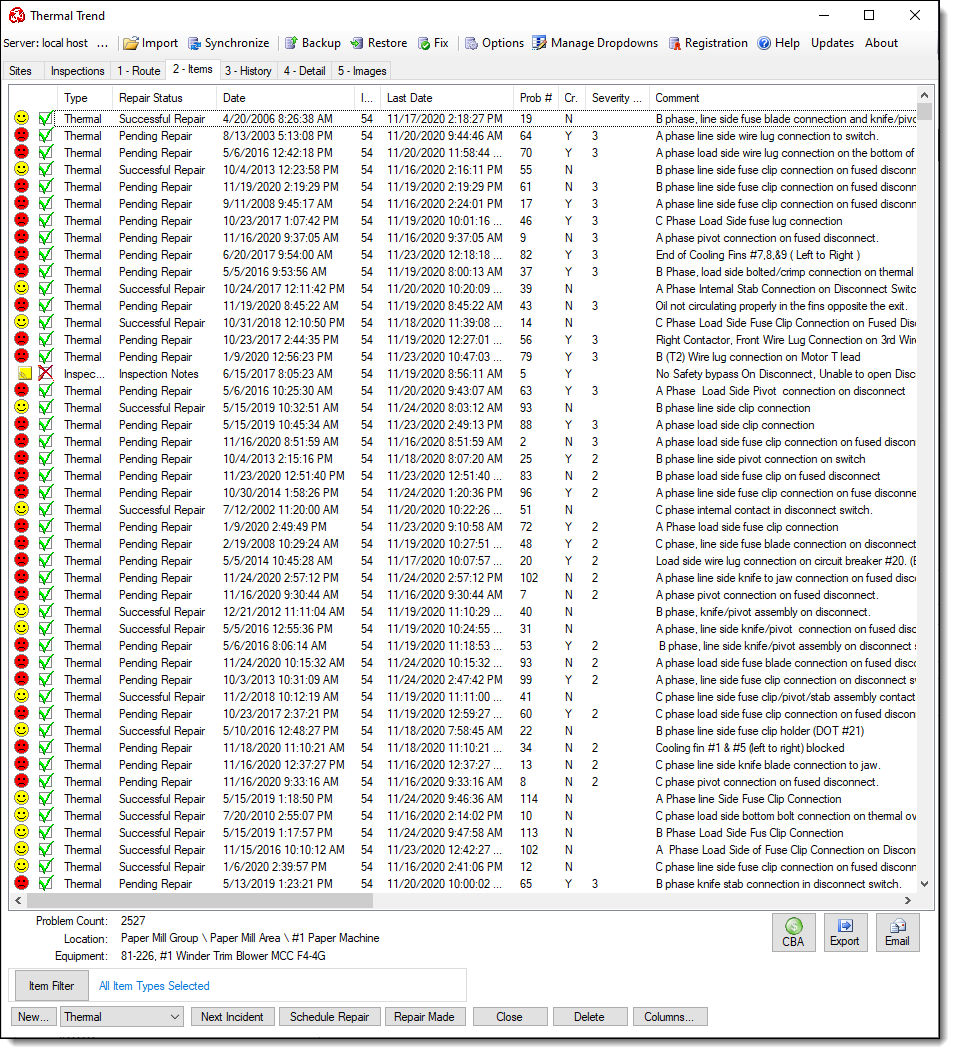

The Items Tab lists all of the associated Items/problems for a specific piece of equipment, location or the Site based on what was selected from the Route tab.

This is were we can drill down into the specific historical details and trending of any problems that have been found. This provides our thermographers the ability to have a complete perspective as to what is going on and advance analysis as to the status of problem condition in the field.

On of the most important parts of any inspection is to have the ability to quickly reconcile all past problems from all previous inspections in the field during the inspection. This is not possible without using Thermal Trend - Lean DB!

Quickly reconcile status of past problems

Items that are found during the inspection are associated with the appropriate equipment that was selected from the Route tab.

This allows you to automatically filter your item list by the entire site, a location, or a specific piece of equipment.

Create, re-document and close Items.

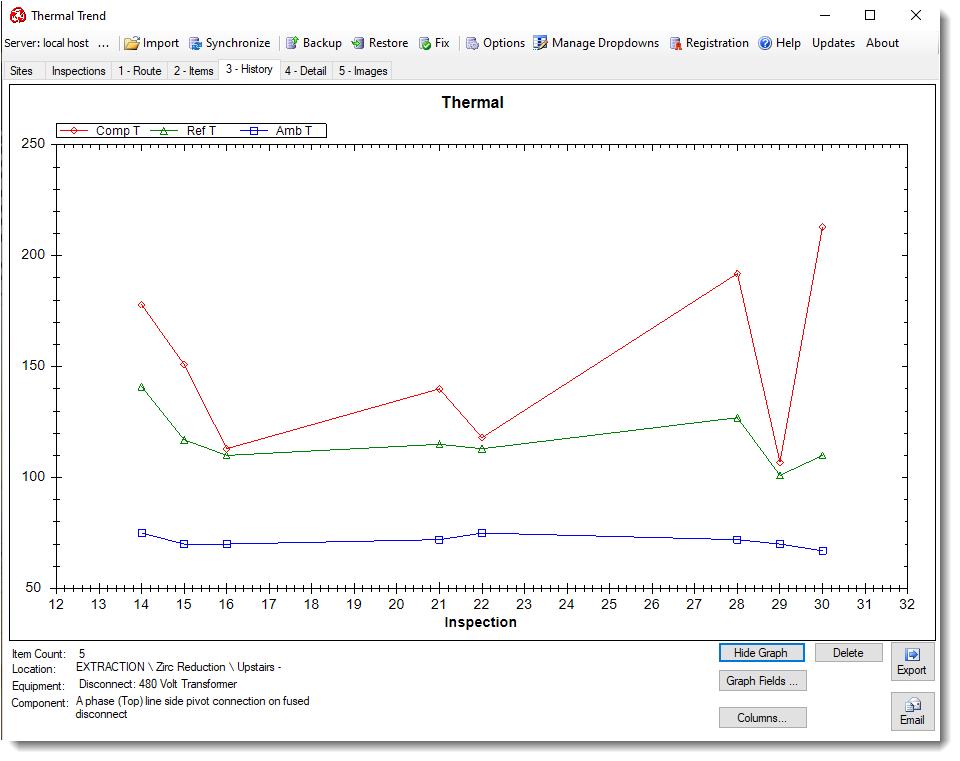

View Time over Temperature Trending and Changes in Severity

You are not always able to correct every problem because of many limiting factors such as, time, spare parts, or being able to take the equipment out of service before the next inspection. Colbert Infrared is able to truly provide you with critical “Time over-temperature trending” of problem conditions. Findings are plotted across multiple inspections automatically showing you trends in the severity of the problems over time. This is of vital importance when having to make decisions about available resources, time and personal to stay ahead of equipment failures.

View Time over Temperature Trending and Changes in Severity

“Time over temperature trending” of problem statuses is tracked over multiple inspections automatically as well as scheduling of repairs and corrective actions. One problem that has been documented in an earlier inspection can have multiple occurrences in the following inspections.

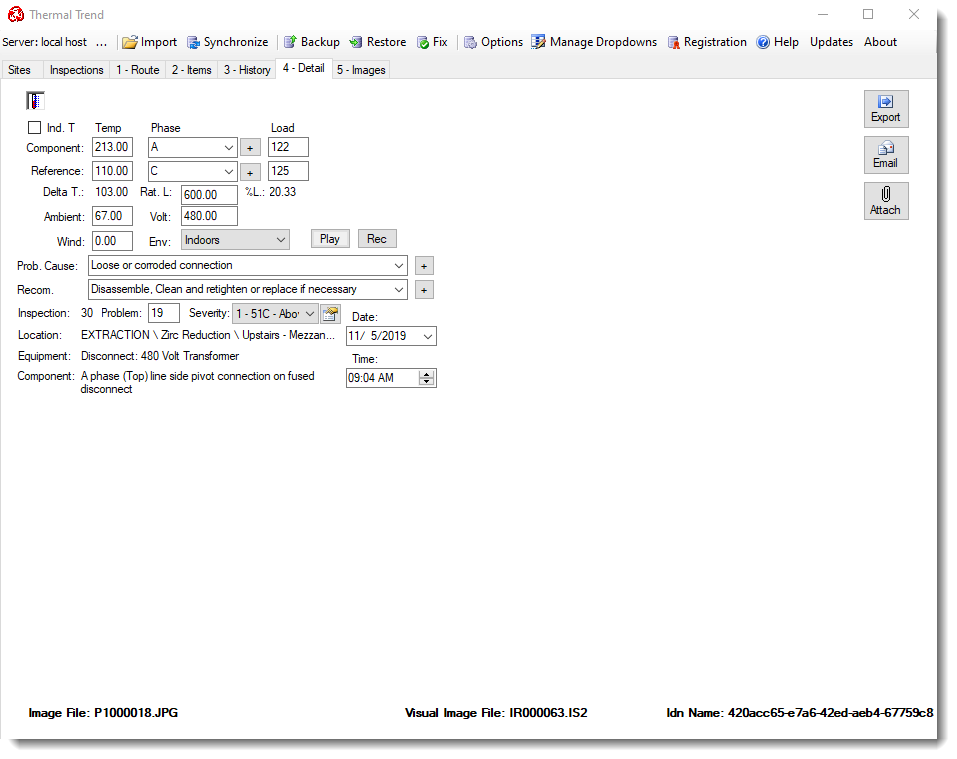

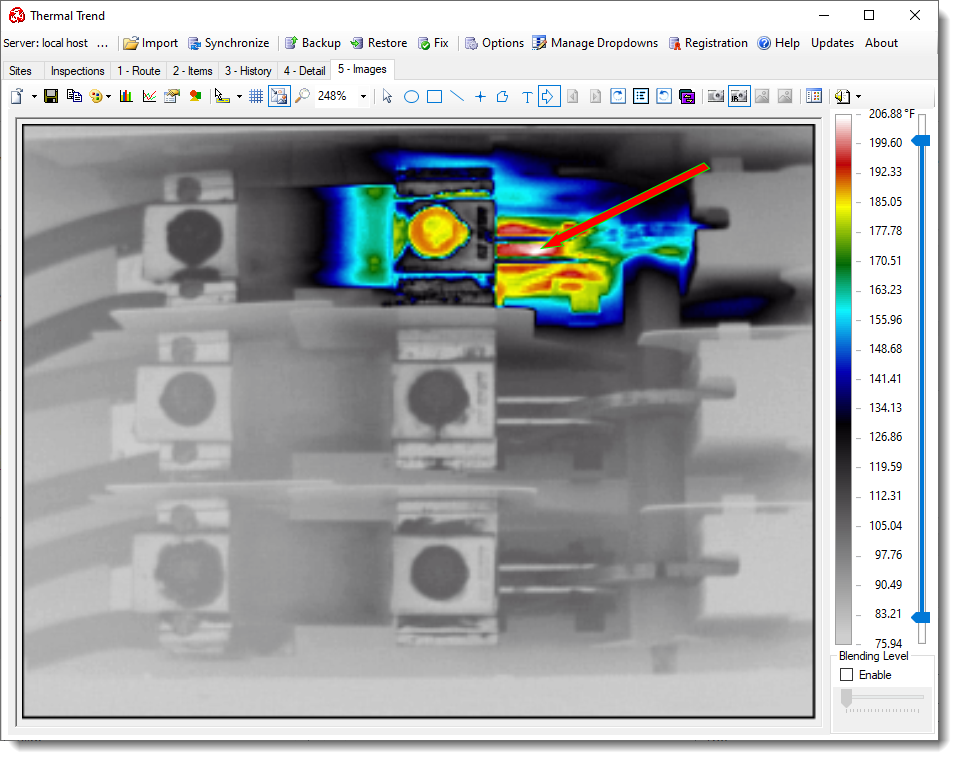

The Detail tab is where we enter new, update or review specific details about a problems conditions.

Review specific details for the different items and repairs!

View past problem data, photos and thermograms. (Works directly with Mikron SIT image files, FLIR jpg files, or standard Windows file formats). Add voice annotation files as attachments for further reference. Enter, update, re-document or close-out Item / Problem data.

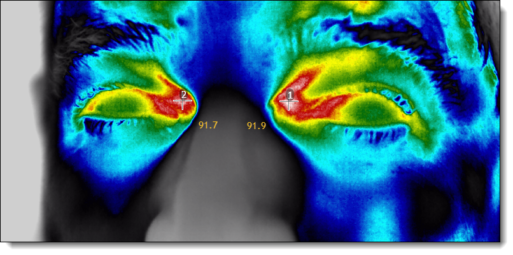

Thermal Trend – Lean give us the ability to do Image Analysis in the field while we are documenting your problem conditions, providing you with the best resolutions to repairs.

Grab the power of Thermal Trend – Image Analyzer for full control of your IR images The power of Thermal Trend – Image Analyzer is incorporated into Lean DB, allowing you full control of your IR images: SIT, IMG, JPG, TIF, IS2 file formats! You have all of the analysis tools in Image Analyzer that you can link directly into the database. No need to have to resave your IR images as bmp files to be able to work with them.

View both IR and visual images.