WHAT WE BELIEVE IN… FRED COLBERT

I started Colbert Infrared back in the ’70s because there weren’t any IR consulting companies that we’re aiming at being leaders, to inspire and innovate as the industry was evolving.

They believed that the status quo was good enough, and if they just keep doing what they had been doing that was enough.

As camera technology was advancing at a tremendous pace and computers and software were entering the market, many companies were just happy using the old IR cameras that they had invested in and were not looking at better ways to do what they did.

“I have always believed that our customers deserve the highest quality services and products and there are better ways to do things. We have been incredibly innovative in our services and products, creating leading-edge solutions, equipment, and software because none existed, and inspiring others to follow our lead in the market.”

And after 40 years of being a leader in the industry, I am asked a simple question….

Why? Why are you still doing this?

“Because I believe in always providing the highest quality services and solutions. It is at our core, and this is what continues to inspire us to find better ways to innovate and lead in our industry. We will never believe that the status quo is just good enough and nor should our customers because they deserve better.”

Why would you except less!

Who is Fred Colbert

Who is Fred Colbert

Fred Colbert, a Certified Level III Thermographer / Instructor with over 40 years of experience in Infrared Thermography is the President of Colbert Infrared, Founder of the Professional Thermographers Association and past chairman of ThermoSense, the world’s oldest and largest conference on Thermal Imaging.

Fred Colbert is a steering committee member of ThermoSense and works with leading thermographers from all over the world and from leading research programs from NASA, Oak Ridge National Lab, JPL, etc.

With worldwide experience in IR program development, camera sales, and software development, Fred Colbert has been truly inspirational in the field of thermal image and has been shaping since the 1970s.

Colbert Infrared’s Story… Why we do what we do

Colbert Infrared’s Story… Why we do what we do

1970’s, U.S Navy, Air Craft Carriers

In the late 1970s, Fred Colbert was performing the infrared inspections for the U.S Navy onboard their Air Craft Carriers. (Each ship for two weeks per ship, while at sea, for the next 5 years). It was the standard operating procedure to meet with the Chief Engineer when arriving onboard the ship, as well as daily, to go over what equipment was to be tested and review what problems had been found.

Managing Inspection Data

All of this led to a great deal of work to have the professional accountability required to answer the questions of the Chief Engineer each day. Many long hours were spent during the evening, after working 8 to 12 hours of inspection time, typing up the report for the next day’s meeting with the Chief Engineer. We could easily have 4 to 6 more hours of work generating the report for the next day.

All of this led to a great deal of work to have the professional accountability required to answer the questions of the Chief Engineer each day. Many long hours were spent during the evening, after working 8 to 12 hours of inspection time, typing up the report for the next day’s meeting with the Chief Engineer. We could easily have 4 to 6 more hours of work generating the report for the next day.

“It was clear that, if you did not have the right information for the Chief Engineer, you have no business being on board the ship… No exceptions!”

You needed to know what and when specific pieces of equipment were to be tested and the status of any repairs on past problems from previous inspections. You were to establish a timeline and route for testing all the equipment and past problems were to be re-inspected (reconciled) so their condition status was updated.

As the inspection was proceeding the Chief Engineer needed to be constantly updated with findings of problem conditions and at the end of each day, a report would be prepared for review.

The thermographer needed to have a complete list of all the equipment (thousands) that were to be “To Be Tested, Tested and Not Tested” as well as the previous histories of each piece of equipment and any associated past problem conditions so that they could reconcile them during the current inspection.

The report

After the inspection, three separate typed, hardbound reports were created. (Note: personal computers were not around at that time, it was all done with a typewriter!) One for the ship, one for the Port Engineer, and one to be kept by the thermographer as a reference copy for the next inspection.

The report included:

- Complete equipment inventory and statuses of tests.

- A prioritized list of problems

- Detailed problem report with thermograms and photos

- “Reconciliation Report” of all past problems.

Breaking out of “The Status Quo”

Whereas back in the ’70s there were not a lot of options as to what you can do. But as time moved forward and technology advance, so did thermography. But the problems were, and in many ways today still. The status quo was just good enough for most consulting companies. But we at Colbert Infrared choose to think differently and look to how technology could advance the data collection and report generation problems of the ’70s and ’80s.

Whereas back in the ’70s there were not a lot of options as to what you can do. But as time moved forward and technology advance, so did thermography. But the problems were, and in many ways today still. The status quo was just good enough for most consulting companies. But we at Colbert Infrared choose to think differently and look to how technology could advance the data collection and report generation problems of the ’70s and ’80s.

In 1990 we created a database that we could use out in the field that would track every asset using bar codes, provide us with all the correct information when and where we need it. The Database is called “Thermal Trend”. It is the premier database solution to managing data and providing high-value reports that our customers can rely on. It tracks the entire life of their facilities equipment.

Thermal Trend provides professional accountability, which the thermographer needs to know while they are performing the inspection in the field.

- What assets/equipment is to be tested?

- What has been tested and not tested.

- What is the best way to group the assets/equipment into some type of route that will allow for a timely inspection?

- Was the equipment inspected in previous inspections?

- Have there been any problems documented on a specific piece of equipment that he is testing (while he is inspecting it)?

- This allows him to review and reconcile past inspection data in real-time to make the appropriate determination as to the existing problem condition.

- If there are past problems that still exist (Open) are they any worse (“chronic” problem conditions)?

Today there are over 1,300 sites, 74,000 locations, 250,000 assess in Thermal Trend that we have been tracking over 6,000 inspections and over 60,000 problems since 1990!

And Thermal Trend is used worldwide by companies for their own internal IR programs from Europe, Asia, Australia to South Africa.

So, when we say:

“We believe in always providing the highest quality services and solutions because it is at our core, and it continues to inspire us to find better ways to innovate and lead in our industry.”

We mean it.

“We will never believe that the status quo is just good enough and nor should you because you deserve better.”

Never accept less!

Looking Forward

Our Future

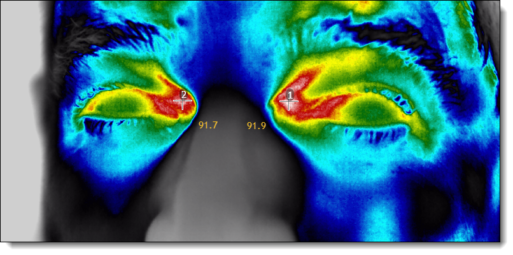

We will never compromise our innovation in providing you with the best in services, products, and support. As Colbert Infrared advances into tomorrow we are always on the leading edge in everything that we do, from our Ultra-High Definition infrared images to our continued development of Thermal Trend and advances image analysis, airborne and UAV/drone applications, and our continued research and development projects.

We have been working hard to earn your loyalty every day, and we will always be there for you!