Colbert Infrared is trusted to guard the the worlds most critical infrastructures where electrical reliability for: generation, transmission and distribution are vital.

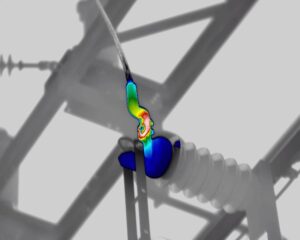

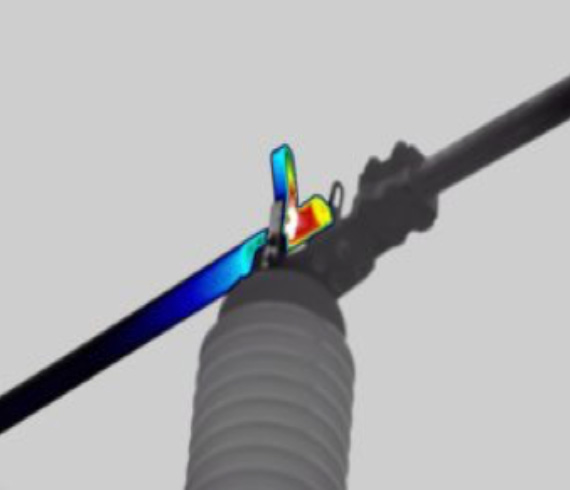

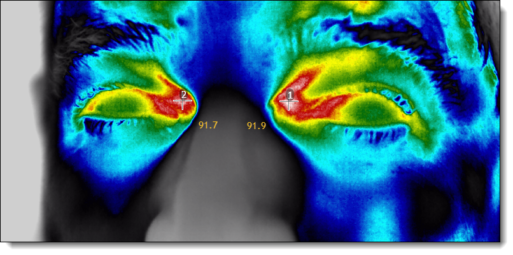

Thermal Imaging is the foundation of maintaining the reliability of the electrical systems, but the camera or images are not most important focus, it is the data that they produce!

Utilizing the “Thermal Trend – Lean” database that completely manages your inspection data, and provides immediate access to in the field critical data and complete history, we are able to leave no stone upturned. With the addition of Ultra-High Resolutions Infrared cameras and lens make sure that have the best solutions for your electrical inspections.