ADDITIONAL INFORMATION

Non-contact temperature measurement gives you the ability to measure and analyze temperature distributions and profiles of many different materials and components in the R & D process.

- Active Thermography

- Aerial Thermography

- Aerospace Industry

- Automotive Industry

- Chemical Industry

- Electronics/Electrical

- Environmental Studies

- Glass Industry

- High-Speed Thermography

- Material Testing

- Medicine

- Metallurgy

- Micro-Thermography

- Photovoltaic Inspection

- Plastics Industry

- Thermal Optimization

- Spectral Thermography

Non-contact temperature measurement in high magnetic fields for the research of the solid matter

Infrared temperature measurements in high magnetic fields were not possible for technical reasons until now. The infrared camera PYROVIEW 640L-PMF is the world’s first IR camera that can measure precisely without contact in permanent magnetic fields of several Tesla. In this way, technical studies on semiconductors, magnetization measurements, nuclear resonance studies, research work in cell biology as well as the determination of critical parameters of high field and high-temperature superconductors can be made for example.

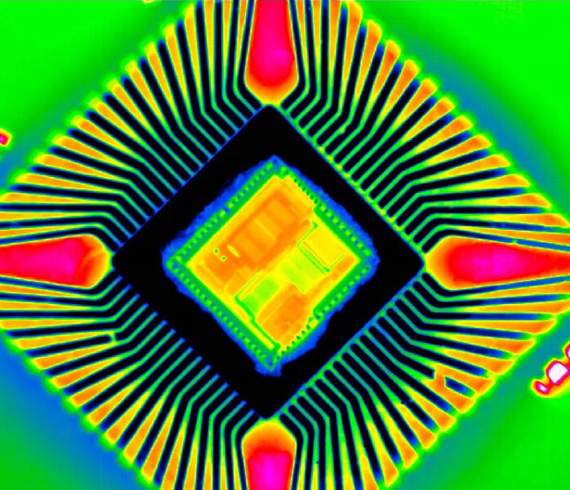

Printed circuit board testing

During the construction process as well as during the manufacturing of circuit boards, infrared cameras can be used to visualize the thermal behavior of single-component parts. This allows faulty modules to be detected and thermal optimization to be implemented

Non-destructive testing of materials using an IR camera – Active thermography

Hair-line cracks, air inclusions, and other manufacturing errors can hardly be detected reliably visual, magnetic, or electrodynamic detected in composite materials. The challenge is non-destructive testing methods for specifically larger areas.

Combustion of biomasses – Non-contact temperature measurement in combustion chambers

the stock of fossil fuels like mineral oil, natural gasoline, and carbon is constantly diminishing. At the same time, their use causes an increased emission of carbon oxide into the atmosphere. Regionally available fuel resources for energy supply are a good alternative but their combustion conditions and their emission decrease should be controlled

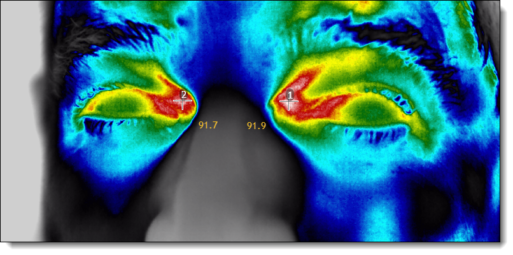

Thermography in veterinary medicine

The challenge: Within the framework of an R&D project “VIONA” (“Veterinary Infrared Orientated Online Analysis system”) the body temperature rise of animals as an important indicator for the diagnostics of diseases has been studied. It becomes apparent using the example of a milk cow flock with 500 animals that a conventional manual fever measurement would be very costly. This task poses also a challenge to the thermography through the

measurement certainty of the absolute temperature should be improved of one order magnitude compared to the conventional infrared cameras.

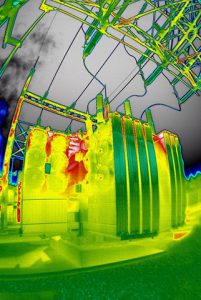

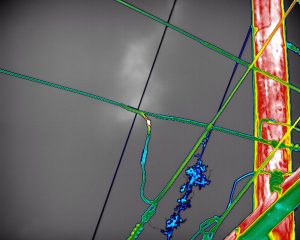

Colbert Infrared has been delivering solutions for Infrared PdM / EPM programs that have set the benchmark for best practices worldwide. Our staff is the highest trained and certified professional thermographers in the industry. Coupled with the most advanced asset tracking and data management solutions for in the field data collection and report generation that ensures that nothing gets missed. And our advanced image analysis capabilities ensure that we can provide you with the image quality and measurement that you exceed your requirements.

Thermal Trend IR PDM Data Management Solution

Based on Colbert Infrared’s 40+ years of expertise working with the U.S Navy onboard their ships, we developed proven professional accountability methods for the inspection of electrical equipment that tracks all equipment history over its lifetime. The software solution that is used it called Thermal Trend and it builds the solid foundation of an EPM program as defined by NFPA 70E and the best practices of 70B.

Using in the field data collection and reconciliation of equipment testing history, based on an MS SQL database where each piece of equipment is barcoded for quick identification in the field. Equipment testing history can be logged and all problems conditions can be documented or reconciled during the inspection in real-time. This way there are no errors in the data because of the necessity of having to type up a report later when you are no longer in the field.

To learn more:

Call us today and let us talk about your needs. (206) 568-4431