Infrared and Capacitance Inspections of Commercial Roofing

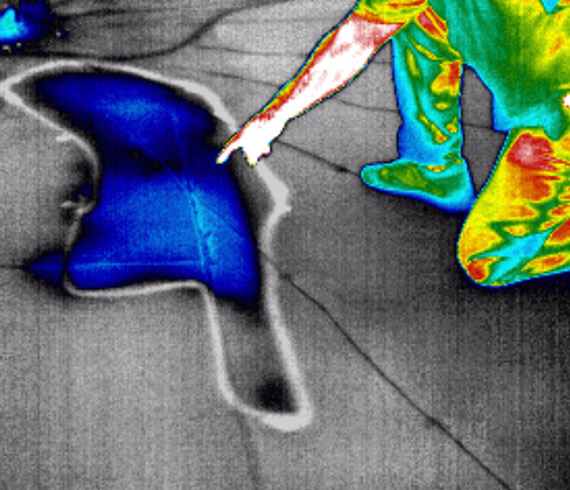

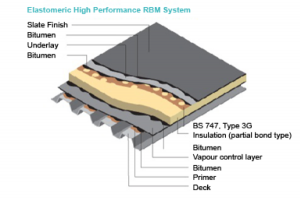

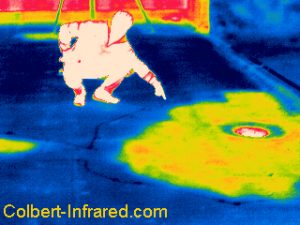

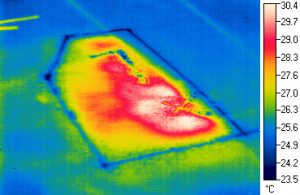

When water gets into a built-up roofing system it changes the thermodynamic characteristic by increasing the thermal capacitance of the wet areas versus the dry areas. In the case to infrared imaging what happens is that the wet area will store more thermal energy longer than the dry areas, and these differences can be viewed at night using a thermal imaging camera depending on the weather conditions and the type of roofing system what was installed.

In some cases, capacitance testing is the preferred method or a combination of both. In either case, Infrared or Capacitance will reduce the amount of destructive testing that would normally be required and yield far better results with better estimates as to the cost of reproofing or repairing the roof system, thereby greatly extending the lifetime of the roofing system and reducing maintenance costs.

Colbert Infrared has over 40 years of experience in conduction roof moisture inspections all over the world. No project is too large for us.

Call us today to find out more as to how we can be of service to you. Phone: 206 568-4431

NFPA, OSHA and IEEE have been at the Vanguard of “Safer by Design”

The National Fire Protection Association (NFPA) regulation 70E provides a reference for facilities to meet the requirements of electrical workplace safety while regulation 70B outlines the best practices for setting up and maintaining an Electrical Preventive Maintenance (EPM) program.

Infrared View Ports and Windows are a key component of” Electrical Maintenance Safety Devices”. Their popularity is growing as companies strive to improve profitability, up-time, and safety. Those who are implementing EMSD based programs are reaping significant benefits in terms of efficiency gains, cost control and fire prevention. Because lower PPE levels are required, inspections are quicker.

Placement of the view port is key!

To ensure that you are getting the best value of your investment, the correct placement of the IR View Ports or Windows is instrumental in optimizing the best viewing angles inside your panels and minimizing your finical investment the amount of View Ports are installed.

Colbert Infrared has been at the forefront because of our extensive history with over 40+ years of experience in Infrared Electrical Inspections. Working with our clients, and knowing where the best place is to place the windows as well as working with installers to ensure the correct placement, is an art, and experience counts!

What Types of Electrical Equipment should have IR Windows? What Types of Electrical Equipment should have IR Windows?

Deciding on which equipment will have IR windows installed should be based on several factors, including the following:

– Frequency of inspections on a given piece of equipment

– Complexity of opening the panels

– Arc flash precautions

– Facility safety requirements

Equipment where IR windows are usually considered include:

– Motor Control Centers: Main Incoming lines connections

– Dry-type Transformers

– Distribution Panels

– High and Medium Voltage Switchboard Cabinets

– Medium & High Voltage Circuit Breakers

Control Cabinets

How to Begin an IR View Port & Window Program?

To begin, establish a list of all equipment that should have IR windows. Prioritize each piece of equipment based on:

– It’s criticality to operation i.e. critical, essential, non-essential

– The consequences of failure.

Plan the installation of the windows starting with the highest priority, taking into account electrical equipment availability (shutdown schedules), the frequency of inspections and hazards.

When purchasing IR windows, consider bulk purchases. In addition to possible discounts, having more windows available will prevent any delays during installation and possibly allow additional windows to be installed if an opportunity arises.

What are the key differences between View Ports, Windows & Grills

Viewports are becoming a very affordable choice for many types of equipment. They are small and can be in key viewing areas where a much large IR Window or Grill would take up too much space. they are the fastest and easiest to install, much lower price, which means that you can install more of them in key strategic locations then IR Windows and Grills. If they are used with a wide-angle lens they will provide superior viewing angle as well, so, for this reason, they may be the best choice depending on your needs and budget.

IR Windows:

Infrared windows consist of a metal or plastic frame that supports an infrared transmissive optic. Infrared windows usually have a protective cover for the optic when they are not in use. Depending upon the window, optics may be made from crystal or polymer material.

What is the Difference Between Crystal and Polymer lens?

Originally, all IR Windows consisted of a crystal lens. Today, Germanium, Zinc Selenide, Calcium Fluoride, and Sapphire are common materials used to make lens.

Crystal Advantages

– Ideal for high ambient temperatures

– Withstands extreme environments

– Allows visual inspections

– Compatible with all IR Imagers

Crystal Limitations

– Limited to 4″ diameter

– Round shape only

– Not impact resistant

– Usually more expensive than polymer

In the past several years, polymer lens has gained popularity. These may be opaque or clear and with or without reinforcement.

Polymer Advantages

– Ideal for industrial environments

– Stable, consistent transmissivity

– Compatible with all IR Imagers

– Impact resistant

– Size and shape options available

– Less expensive than crystal

Polymer Limitations

– Not suitable for high-temperature environments (over 200°C)

– An expert should be consulted before ordering custom sizes or shapes

The National Fire Protection Association (NFPA) regulation 70E provides a reference for facilities to meet the requirements of electrical workplace safety while regulation 70B outlines the best practices for setting up and maintaining an Electrical Preventive Maintenance (EPM) program.

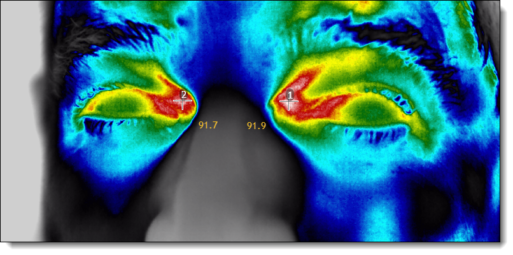

One of the tasks that need to be completed on electrical equipment whilst it is energized and under load is infrared (IR) scanning. IR cameras can only measure what they can see and cannot see through glass or plexiglass viewing windows commonly fitted in switchgear.

For IR inspections to be completed while the equipment is under load, the use of an IR viewport or window, (an Electrical Maintenance Safety Services or EMSD), that allows an IR camera to see the energized loaded connections through a special lens material in the IR windows.

This allowing the switchgear to remain closed and in a safe and guarded condition ensuring that the inspector is never exposed to the dangers of arc flash or electrocution.

Much of the recent acceptance of IR windows has coincided with the increase in the level of awareness regarding electrical safety, risk reduction, and arc flash. Organizations such as the IEEE have been at the vanguard of this movement with its “Safer by Design” campaign. In response, switchgear manufacturers are increasingly installing IR window at the point of manufacture.

IR View Ports & Window Options

With Colbert Infrared’s 40+ years of expertise in the infrared industry provides you assurance in helping with the placement, selection and purchasing options from an extensive list of the manufactures many products and offerings. Every manufacturer has their strengths so choosing the best products based on the working environment, ease of access and budget limits are important in making sure that you get best out of your investment.

- Infrared Cameras Inc.

- IRISS

- Exiscan

- FLUKE

Call us today and let’s talk about your needs. (206) 568-4431