DATA CENTERS

The data center continues to be a critical part of the business. Beyond anything else, we’re going to see new kinds of demands and business requirements which will impact the way we leverage technology and the entire data center model. When it comes to keeping the data center up and running, having a solid Infrared Predictive Maintenance Program is key.

Our world is increasingly becoming connected and digital. The latest Cisco Visual Networking Index indicates some interesting trends going into 2021:

- Annual global IP traffic will reach 3.3 zettabytes by 2021. In 2016, global IP traffic was 1.2 ZB per year or 96 exabytes (one billion gigabytes) per month.

- Global IP traffic will increase nearly three-fold over the next five years and will have increased 127-fold from 2005 to 2021.

The US Department of Energy estimates that there are about 3 million data centers in the United States. That’s 1 data center for every 100 people. Scattered across the nation, these energy-intensive complexes require a lot of power and electricity to run the internet—at big costs.

Unique Problems

With regards to the electrical system, there are some unique problems that many Data Centers face across the U.S.

Data center energy use has grown rapidly in recent years. And it’s expected to continue to grow. In 2013, U.S. data centers consumed about 100 billion kilowatt-hours of electricity, representing more than 2% of all U.S. electricity use.

Up-time is Critical

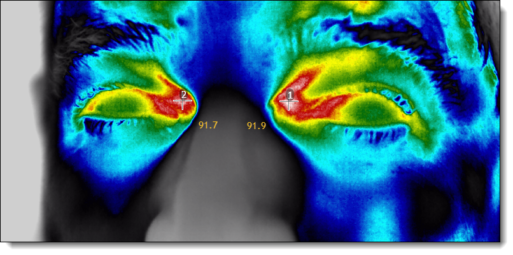

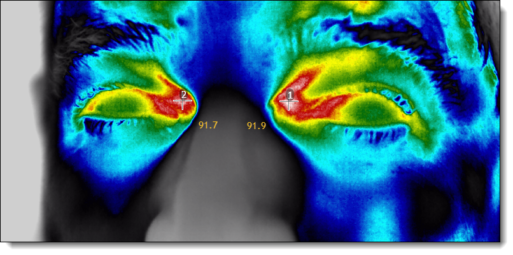

Electrical failures, even in seeming small circuits can have a domino effect that may cause upstream equipment to shut down. If these problems are not addressed quickly, they can gravely impact the requirements for cooling, redundancy, management, and other power sources. Just simply performing an IR inspection is not enough, you need to have an IR Program that takes into account all of the historical data and presents it a way that critical decisions can be based on.

Challenges that Data Centers face:

- Oversimplification of the requirements for preventative /predictive/condition monitoring testing is required to do a professional job.

- Turnover in engineering staff where the tribal knowledge has not been able to be passed on to the next person, leading to attrition in the general knowledge of the facility and a much longer learning curve for new employees.

- Not having the necessary schema of where equipment is feed from and what it feeds or where it can be found quickly in an emergency.

- Not having a concise method of inventory management that catalogs the test status of equipment and their associated problem history over time.

- Inability to correctly determine the Critically to Operation (CTO) of the electrical equipment (what is critical, essential and non-essential equipment) because of a lack of quality data at hand for review.

Colbert Infrared Solution

For over 40 years Colbert Infrared has been working in providing advanced electrical/mechanical infrared imaging utilizing the best equipment and inspection procedures by highly trained and experienced professional certified infrared thermographers, combined within the field data collection, reconciliation and analysis utilizing a mobile database solution called Thermal Trend – Lean.

- Thermal Trend – Lean allows Colbert Infrared to quickly and easily inventory all the equipment, associate it with a bar code for fast identification, and log all testing and problems found in the equipment for trending of the problem conditions over time.

- This world-class solution allows Colbert Infrared to build out a complete picture of entire electrical system for understanding the schema and the interdependence’s of each piece of equipment and allowing for the correct classification of the Criticality To Operation “CTO” as it relates to the reliability of the operation of the data center.

- With all of the equipment history, just like a “Medical Record” it’s immediately available in the field, while they are in front of the equipment. They can evaluate and analyze the problems with all of the data when and where they need it.

Colbert Infrared – World Class Innovations that never stops!

When you have the complete picture, you can gain a perspective that you could not have achieved any other way. The advanced reporting that is generated by the Thermal Trend – Lean DB provides our clients with all the critical information that they need to make informed decisions with. But we don’t stop there. Since all of the data is stored in a “Real” database, we and further the analysis by using advanced Business Intelligence software that provides our clients with direct access to their data in a user friendly, graphical interactive web-based solution “Thermal Trend – Insight” that allows them to explore even deeper to better understand what is going on in their facilities.

Please give us a call or email us so that we can help to informer you better about the innovative solutions that we can provide to your facility.

<a href="tel: (206) 568-4431 onclick="ga('send', 'event', { eventCategory: 'Contact', eventAction: 'Call', eventLabel: 'Mobile Button'});"><p class="call-button">Click to Call</p></a>